| Name: | DDG-2080D multi-channel online conductivity meter |

|---|---|

| Measuring range: | 1.0~20.00uS/cm(K=0.01) 0~200.0uS/cm(K=0.1) 0~2000uS/cm(K=1) 0~20.00mS/cm(K=10) 0~600mS/cm(K=30) |

| Resolution: | 0.01uS/cm |

| Accuracy: | ±2.0%F.S. |

| Temperature compensation: | 0~100℃ NTC 10K (auto) |

| Output: | 4~20mA |

| Communication interface: | RS-485(optional) |

| Power supply: | AC220V±10% 50/60Hz |

1. Standard: JB/T 6855-93 <<Industrial conductivity meter >>

2.Conductivity measuring range : 0.01~20μS/cm(Electrode: K=0.01)

0.1~200μS/cm(Electrode: K=0.1)

1.0~2000μS/cm(Electrode: K=1.0)

10~20000μS/cm(Electrode: K=10.0)

3. Intrinsic error of the electronic unit: conductivity: ±0.5%FS, temperature: ±0.3℃ (0~60℃ ).

4. Range of automatic temperature compensation: 0~99.9℃, 25℃ as the reference temperature.

5. Water sample tested: 0~99.9℃, 0.6MPa.

6.Intrinsic error of the instrument : conductivity: ±1.0%FS, temperature: ±0.5℃

7. Automatic temperature compensation error of the electronic unit: ±0.5%FS

8. Repeatability error of the electronic unit: ±0.2%FS±1 Unit

9. Stability of the electronic unit: ±0.2%FS±1 unit/24h

10. Isolated current output: 4~20mA (load<750Ω)

11. Output current error: ≤±l%FS

12. Error of electronic unit caused by ambient temperature: ≤±0.5%FS

13. Error of the electronic unit caused by the supply voltage: ≤±0.3%FS

14. The instrument channel has two to four channels for selected; all the channels are mutually independent. (When ordering, please specify the number of channels, it will matching dual channel if not specified.) Data of each channel are measured and displayed at the same time , without switching display.

15. Power supply: AC 220V±22V, 50Hz±1Hz; DC24V (Optional)

16. Protection grade: IP65

17. Overall dimension: 146 (length) x 146 (width) x 108 (depth) mm; dimension of the hole: 138 x 138mm

18. Weight: 0.5kg

19. Working conditions: ambient temperature: 0~60℃; relative humidity <85%

20. The conductivity electrodes with the following five constants are usable: K=0.01, 0.1, 1.0, 10.0, and 30.0. When ordering, please specify the electrode constant.

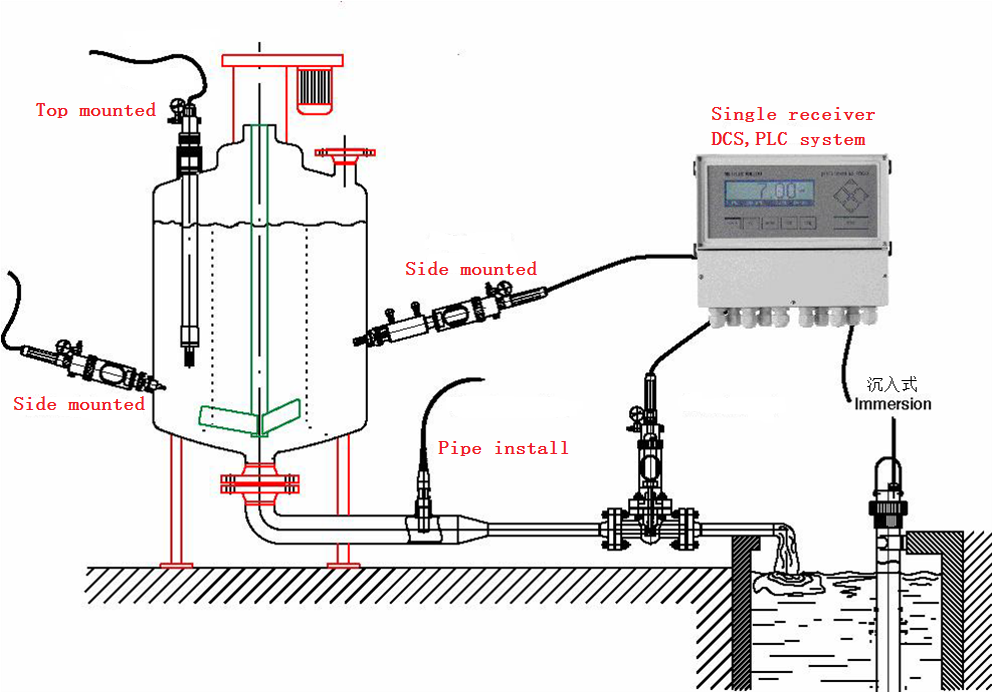

21. The installation type of secondary meter: Opening type, Wall mounting type, Frame mounted and pipeline type.

Customers can arbitrarily choose Dual channel conductivity meter, three channel conductivity meter or four channel conductivity meter. All the channels are mutually independent, none interfering, and most can be connected with four electrodes at the same time.

English liquid crystal display, English menu operation.

Computer-based: It adopts the high-performance CPU chips, high-precision AD conversion technology and SMT technology to complete the multi-parameter measurement, temperature compensation and automatic rang switching, with high precision and good repeatability.

Phase-sensitive detection: With such detection, the impact of wires on conductivity measurement can be eliminated.

25℃ conversion: Temperature compensation automatically measured / manual input.

Waterproof and dustproof design: The protection grade is IP65, and it is suitable for outdoor use.

Isolation of 4 ~ 20 mA current output, discretionary setting of upper and lower thresholds for the current corresponding to conductivity value output

DDG-2080D conductivity meter can choose between two to four channels, a multi channel conductivity meter is equivalent to two to four conductivity meter.

Sewage treatment

Aquaculture

Circulating water treatment

Dosing control

Biopharmaceutical

Fermentation

Chemical Industry

Power plant

Influent water treatment

Pretreat influent water before it enters your plant’s system. Proper influent water monitoring is the first defense to protecting the health of your equipment and preventing corrosion. By properly treating water at this stage, you can reduce costs and treatment within the power and steam generating process.

Steam and power generation

Protect your equipment – from pipes and tubes, to turbines and boilers – by ensuring your water is of the highest quality. Minimize silica levels to prevent turbine blade erosion, and monitor and manage dissolved oxygen (DO) to prevent corrosion.

Cooling water

Ensure heat transfer processes are as efficient as possible by effectively controlling total suspended solids (TSS) to avoid the expense and downtime associated with fouling and mineral buildup that can cause scaling and hazardous operating conditions.

Industrial wastewater

Ensure compliance with all discharge requirements. Our industrial wastewater solutions help you minimize environmental impact and ensure compliance with permits.